|

Apparently

it was a design aim of the factory to eliminate the fork-lift truck as

far as was practicable and certainly there were very few in evidence.

Great emphasis is also laid on making the tracks wide and flat enough

for workers to travel along with the job, moving back to the next

station when they finish.

Aulnay is not heavily manned in relation

to its size. There are 5,500 workers in total, of whom 4,800 are on the

production lines. The proportion of immigrant labour is high, well over

half, with Vietnamese as well as North Africans very much in evidence.

The production task is of course simplified by, having to produce only

one model, though these days the CX comes in a number of variations.

The standard saloon has been joined by the estate car somewhat behind

schedule, one gathers, running properly for a couple of months only,

accounting for about 10 per cent of production but increasing), the

Diesel (16 per cent of all CX production) and a surprising number of

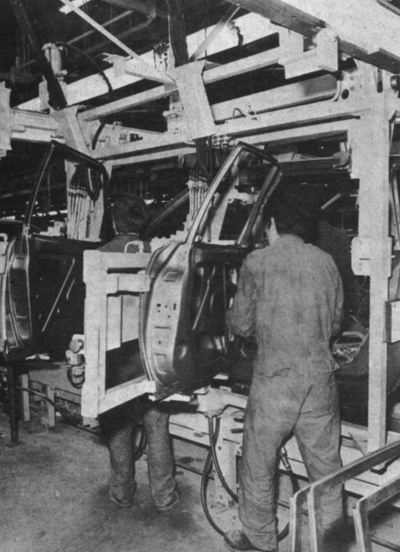

the longer-wheelbase Prestige saloons. Body welding-up is done in

large, fully-automatic jigs rather than the welding robots which are

achieving wide popularity elsewhere; much of the machinery is French.

So far, 140.000 CXs have been built in less than three years with 25

per cent - the proportion is rising - going for export.

At the moment the body assembly shop is noticeably “loose” with an air

of relative leisure and several empty stations on each line. It is

noteworthy that Aulnay’s expansion plans call for a press shop, and

doubled final assembly capacity, but no increase in the body assembly

facility. Clearly this is big enough already, and it means also that

CitroŽn (and Peugeot) are more or less committed to carrying through

the Aulnay expansion plans in full. By that time it should be capable

of producing well over 1,000 cars a day. When this capacity is added to

that of the enormous Rennes factory, which employs l2,000 people and

builds all GS and Ami 8 models, one begins to realise that in the next

decade CitroŽn - let alone Peugeot-CitroŽn - will be a force to be

reckoned with.

|