|

||||||||||||||||||||||

CITROËN AND HYBRID AIR TECHNOLOGY: A HIGH-TECH OFFENSIVE FOR ENVIRONMENTAL PERFORMANCE |

|

After pioneering the particulate filter and Stop&Start, leading the way in diesel hybrid technology with the Hybrid 4, and being the first to market an electriccar, CITROËN is continuing the offensive at the Geneva Motor Show with another high-tech breakthrough: the Hybrid Air system. A full-hybrid solution combining compressed air and hydraulic power, Hybrid Air draws upon expertise that is written into the Marque’s DNA. It is an innovation that reflects CITROËN’s consistent aim of developing technologies available to everybody and for all types of use. Hybrid Air delivers breakthrough performance with fuel consumption of less than 3 litres/100 km and no additional battery, for:

|

|

|

This revolutionary technology is particularly well suited to models in the B and C segments as well as LCVs. On the Marque’s stand at the Geneva Motor Show, it can be seen on a CITROËN C3 prototype that boasts record-breaking fuel consumption of 2.9 l/100 km (69 g of CO2/km). It also cuts fuel consumption and CO2 emissions by 45% in urban driving, compared with an ICE vehicle fitted with the same engine. Karim Mokaddem, Hybrid Air project manager, will be present during the press days. He will respond to requests for interviews and explain how Hybrid Air technology works, with details on operation and performance figures. Several events will be organised in front of the C3 Hybrid Air prototype, on 5 March 2013 at 2:00 pm, 3:00 pm and 4:00pm and on 6 March 2013 at 10:00 am, 11:00 am and midday. |

|

|

AN INNOVATION WRITTEN INTO THE MARQUE’S DNA At Geneva, CITROËN is presenting Hybrid Air technology, a unique system developed by PSA Peugeot Citroën in cooperation with the Bosch® group and drawing upon the historic expertise of brand engineers in hydraulic systems for cars. In 1955, with the DS, CITROËN launched a spectacular innovation: a system combining pressurised air with high-pressure hydraulics to control and manage the suspension, steering braking and semi-automatic gearbox. In 1958, CITROËN engineers developed a prototype 2CV, a hybrid vehicle using pressurised air and hydraulics to boost the combustion engine. However, as there was no real market for the car, and technologies were lacking for its mass production, the project never became a reality. In 2013, Hybrid Air technology is revolutionising the car industry. |

|

|

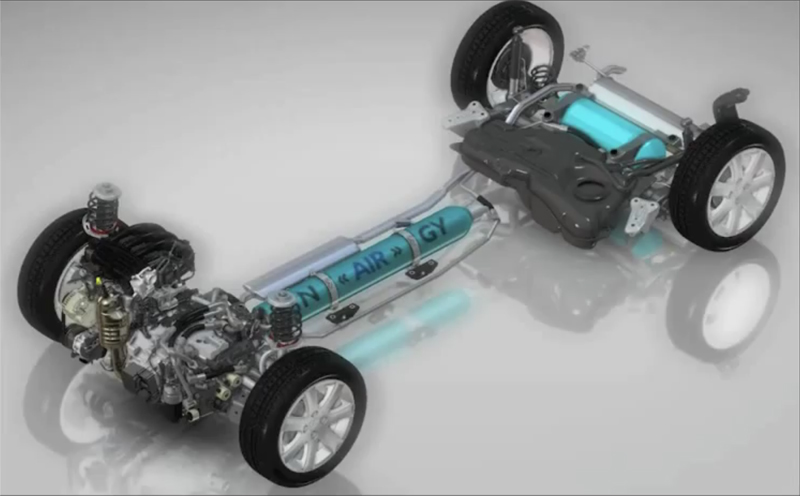

HYBRID AIR: COMBINING A PETROL ENGINE WITH COMPRESSED AIR THROUGH THE USE OF HYDRAULIC POWER Hybrid Air relies on proven sub-systems and technologies: a PureTech petrol engine, a compressed air energy storage unit, a hydraulic pump/motor unit and an automatic transmission with an epicyclic gear train. Eighty patents were filed by the PSA Peugeot Citroën Group during the development process. An intelligent electronic management system manages input from the driver to optimise energy efficiency. Three operating modes are available:

|

|

|

TECHNOLOGY FOR ALL CUSTOMERS

Adapted for a CITROËN C3 VTi 82, the Hybrid Air system slashes fuel consumption by one third to achieve a record-breaking 2.9 l/100 km over a combined cycle, with CO2 emissions of 69 g/km. In urban driving conditions, the reduction in fuel consumption is around 45%.

Hybrid Air technology uses no additional batteries, so could be sold at an attractive price on both European and international markets. The technology operates at a constant level of efficiency, regardless of weather or driving conditions. It could be developed not only in Europe, but also on all the other markets where the CITROËN brand is present. Easily adaptable for both passenger cars and LCVs, it is particularly efficient on B and C segment vehicles. |

|

|

A technology that makes no compromises The presence of the Hybrid Air system has no influence on interior space or boot capacity. The decision to opt for a system that is essentially mechanical simplifies servicing operations and makes for easier recycling at the end of vehicle life.

Lower fuel consumption and CO2 emissions go hand-in-hand with significant improvements in driveability, thanks to:

System operation is smooth and completely transparent for customers. HYBRID AIR TECHNOLOGY IN

DETAIL |

|

|

TECHNOLOGIES ACCESSIBLE TO EVERYBODY AND FOR ALL TYPES OF USE

|

| ℗

15th February 2013 SA

Automobiles

Citroën/Citroënët

|