|

||||||||||||||||||||||

THE

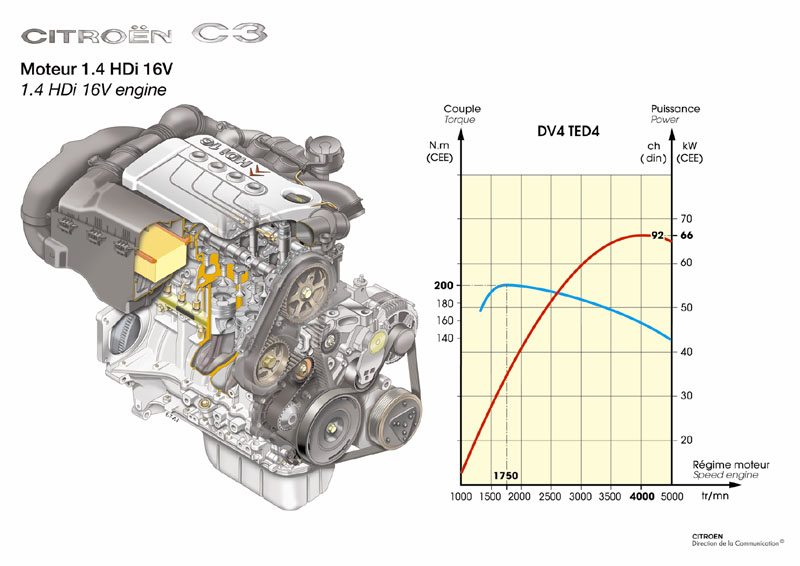

ADVANTAGES OF THE 1.4 HDi 16V ENGINE

THE

CITROEN C3 15 THE FIRST VEHICLE TO BE FITTED WITH THE NEW

GENERATION 1.4 HDi 16V ENGINE DEVELOPED THROUGH THE COOPERATION

AGREEMENT BETWEEN PSA PEUGEOT CITROEN AND FORD. AS A RESULT OF

THE TECHNOLOGICAL CHOICES MADE (CYLINDER HEAD DESIGN,

SECOND-GENERATION COMMON-RAIL SYSTEM, VARIABLEGEOMETRY

TURBOCHARGER AND DIRECT INJECTION), THIS ENGINE GAINS A LEVEL OF

QUIET, ASSURED PERFORMANCE HITHERTO SEEN ONLY IN HIGH-SPEC

VEHICLES.

The performance of

the 1.4 HDi 16V engine is quite simply astonishing for a vehicle

in this category, particularly with respect to mid-range

acceleration and response, these being the conditions most

frequently encountered in use.

Easy and

enjoyable to drive, this engine has a strong and appealing

personality of its own.

Thanks to the

second-generation common-rail system, the 1.4 HDi 16V combines

improvements in torque, performance, fuel consumption and

pollutant emissions, with quiet operation and compact design.

OPTIMISED

PERFORMANCE AND EFFICIENCY

The 1.4 HDi 16V

engine develops 66 kW EEC (92 bhp DIN) at 4,000 rpm and torque

of 200 Nm at 1,750 rpm. It is the most efficient engine in its

segment (47 kW/litre and 66 bhp DIN/litre).

The reduction

in weight of the moving parts contributes to engine performance

by making it possible to increase speed more quickly, in the

same way as with a petrol engine.

Equipped with

second-generation common-rail injection technology, a variable

geometry turbocharger (multivalve technology) and an air-to-air

intercooler, this new engine applies specific control laws,

through which it is able to adapt to driver behaviour by

adjusting output in accordance with the pressure placed on the

accelerator pedal.

LOWER

CONSUMPTION

The 1.4 HDi 16V

is an engine of parsimonious fuel consumption (4.3 litres/100 km

in a combined cycle) as a result of its low capacity, advanced

design materials (aluminium alloys and composite materials) and

lower internal friction combined with the use of common-rail

direct injection technology. One way of cutting fuel consumption

is to reduce the weight of vehicle components. With a total

weight of around 98 kg, the 1.4 HDi 16V engine is a real

"featherweight". This reduction in weight was achieved through

the general use of aluminium alloys and composite materials.

The cylinder

block and cover are made of pressure cast aluminium, with

cast-iron bearings and sleeves inserted during the casting

process.

The cross-flow

cylinder head, comprising four valves per cylinder, is made up

of two sections: a tower gravity-cast section and an upper

section bearing the pressure-cast camshaft.

The camshaft

features sintered cams that are fitted onto a steel tube. This

design reduces the weight of the assembly by 30% or 1.3 kg.

A number of

components are made of composite materials, including the intake

manifold, cylinder head cover, water inlet and outlet housings

and the treatment system for crankcase fumes.

All the moving

parts (such as the crankshaft, rods and pistons) have been

optimised with a view to reducing size and weight. The diameter

of the valve stems, for example, is 5.5 mm. This is a size more

commonly found in small, high-performance petrol engines.

Another factor that plays a role in reducing overall consumption

is the reduction in friction losses. The valves are controlled

by finger followers that cut fuel consumption by between 1.5%

and 2% depending on engine speed.

Last, the

high-pressure common-rail injection system provides a fine,

high-precision fuel spray and contributes to the management of

fuel consumption. A single rail supplies the four injectors with

fuel at a pressure varying from 250 bars to 1,400 bars.

These new

electronically controlled injectors calculate the timing and

quantity of fuel injection with precision, particularly for the

pilot injection (or preinjection).

ACOUSTIC

COMFORT AND VIBRATION CONTROL

The 1.4 HDi 16V engine offers excellent acoustic comfort and

vibration control as a result of its specific characteristics

and its positioning under the bonnet of the C3, using a system

of specialty adapted shims and mounts.

The pilot

injection (small quantity of fuel injected before the main

injection) gradually increases the temperature in the combustion

chamber and brings about gradual combustion with a significantly

higher level of acoustic comfort, notably at idle.

The highly

elaborate exterior shape of the cylinder block - obtained by

pressure casting - and the precise ribbing used to stiffen the

lower part, also contribute to the low emissivity of the engine.

Last, the use of

lighter mobile parts reduces engine inertia and so improves

vibration control.

RESPECT FOR THE ENVIRONMENT

Combining

new-generation common-rail technology with improved combustion

management and reduced weight, these low-capacity diesel engines

enhance performance levels and bring significant cuts in fuel

consumption and C02 emissions with no trade-off in vehicle

performance.

The 1.4 HDi 16V

Engine emits 112 g of CO2 per km, an exceptional result in view

of its performance characteristics.

COMPACT

DESIGN

The compact

dimensions of the engine made it possible to modify the layout

of parts underneath the bonnet with a view to increasing

passenger protection.

The layout of

the parts around the engine such as the exhaust, accessories and

air-intake has been defined to take up less space.

The air supply

system behind the engine, which is made of composite materials,

provides a compressible area in the event of impact.