|

Aerodynamics

is all the rage. Many a motor manufacturer in search of fuel economy is

now discovering this science, which is also an art.

As was the case for the "traction

avant"

- or front wheel drive car, this is one of the fields in which Citroën

has been disporting for many years. Followed today by many others.

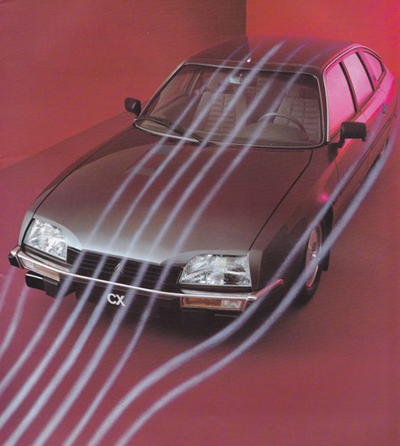

During the year 1979, the German magazine "Stern" wind

tunnel tested ten cars - and noted the GS's

aerodynamic superiority.

A

year later, the newspaper "Die Welt" remarked that the lines of the

"cars of the future" currently elaborated by stylists have in fact been

in existence since 1974: they are those of the Citroën CX

, the car with the apt name (the Cx of a car is its coefficient of

penetration through the air). Other observers noted that such and such

so-called experimental models, French or foreign, intended for the

years 1982-85, are still far from reaching the Cx of the standard

production Citroën GSA X3. A German Consumer Association wrote to

Citroën precisely to cast doubts on the real value of this model's CX.

The marque thereupon provided all the proofs:

The

Cx of the GSA X3, as measured at the Aerotechnical Institute at

Saint-Cyr l'Ecole, with two occupants (310 lbs) and 130 lbs of luggage

aboard, with the engine running to maintain a normal road clea-rance,

is in fact 0.318. The Consumer Association took cognisance of this and

naïvely admitted: "The specialists who advised us were of the opinion

that such a sensational value was practically unattainable". Yet it is

the best Cx in the world for a standard production car. Thanks for

recognising the fact!

All over the

World, the Cx battle rages, with penetration coefficients as its

weapons. Hardly have they been discovered when attempts are already

under way to manipulate them. It is now useful to take stock: what is

aerodynamics to-day?

1 The science of the wind

Aerodynamics

is an experimental science whose aim is the study of the relative

motions of a solid body with regard to the surrounding air. Its

application to the design of a car body constitutes one of the chief

lines of the quest for energy economy in motor vehicles.

In order to move over the ground, a body must overcome

two forces:

-

resistance

to tyre tread motion, which is dependent on the state of the surfaces

in contact and proportional to the vehicle's mass. The slower the

vehicle moves, the greater its effect.

-

resistance

to forward motion, which depends on the shape of the body and on its

frontal area. The higher the speed, the greater its effect.

All

this leads one to see in motor-car aerodynamic research a means of

reconciling economy and comfort while respecting the imperatives of

safety.

In the XVIth century, the

first, measurements of air resistance were carried out on freely

falling bodies, and it was only at the end of the XIXth century that a

new method appeared: submitting the body to be studied to an artificial

air stream. It is on this principle that wind tunnels work.

The

initial means of ventilating wind tunnels was compressed air, then the

fan, first used as a blower, and later (as is now the case) for

suction. In 1909, the well- known engineer Eiffel added two essential

devices: an intake and a diffuser. This type of wind-chamber is the

prototype of all present day tunnels.

In

applications of motor car aerodynamics, the cross section of the

experimental chamber is of the order of 15 to 20 m2 (160 to 215 sq.

ft.), i.e. 10 to 20 times the vehicle's cross-section. In the main

stream, wind speed reaches 100 mph with a stability of ±1% in

experimental time and space.

This homogeneity is fundamental, as is a low

ground-limit layer (dead fluid zone).

Automotive

aerodynamics also relies on reduced scale wind tunnels for use with

models, the scale usually being 1/5. These preliminary shape-research

trials, quicker and less costly than full-scale ones, eliminate gross

errors on the first prototypes.

Wind-tunnels

are fitted with relatively complex dynamometric devices allowing

measurement of all aerodynamic forces. The car-dynamometer system forms

a unit which can be turned through a certain angle relative to the

wind, thus allowing the simulation of side wind.

It

should however be borne in mind that there is no universal standard for

these measurements. Each wind tunnel itself constitutes the standard

for the experimental research done there. From one wind tunnel to

another, there may be dynamometric or blown-wind dispersions provoking

slight distortions between the results found with one or another

tunnel. For this reason, it is always well to know where and in

what circumstances the measurements put forward were made.

It

is, in particular, important to know whether the results stated were

obtained with a full-scale car, rather than with a 1/5 scale model

(whose aerodynamic results are generally about 20% better), but also

whether the car was a real one, and loaded.

All

coefficients Cx Cy Cz Cl Cm Cn are read in the wind tunnel for various

angles of side-slip ß (angle between the axis of the vehicle on test

and the axis of the wind tunnel).

Running at 80.8 mph

with a 25 mph side wind is simulated in a wind tunnel by an 84.5 mph

wind and an angle of 17 degrees between the model and the wind.

Vo = 84.5 mph (136 km/h)

Vl = 25 mph (40 km/h)

Vv = 80.8 mph (130 km/h)

ß = 17 degrees

Knowing

the distribution of weights and lifts on the front and rear axles, it

becomes possible to calculate the weight taken off the wheels at all

vehicle speeds with different side winds.

For

instance, for a standard vehicle with a total weight of 2 640 lbs (1760

lbs forward, 880 lbs rear), the weight taken off the front axles

may be 1 000 N (216 lbs) at 93.6 mph with a 50 mpg side wind, whereas a

racing car may have a weight lift equivalent to the axle load.

Using

forces and moments, it becomes easy, by simple computation, to define

the position of the centre of lateral thrust in relation to the centre

of gravity. Together with lift, this is one of the criteria of road

stability.

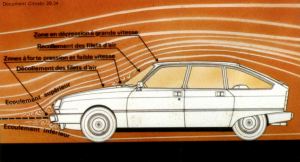

2 Visualisation of air fillets

Visualisation

of air-flow is indispensable to the comprehension and analysis of the

results founded. Two methods are in current use:

The

study of air-flow patterns makes it possible, among other things, to

look for means of compensating any aerodynamic effects which might

oppose the operation of certain components of the car. Nothing is ever

simple! Thus the (highly desirable) improvement of a vehicle's

coefficient of drag may prove detrimental to the cooling of the braking

system (highly regrettable).

This is

why, during wind tunnel tests, the temperature of various

braking-system parts is monitored. The visualisation of air fillets

then makes it possible to design practical means of air supply to

ensure the indispensable cooling of disc brakes.

Example:

the aerodynamic study of the Citroën CX led to the setting up of an

elaborate braking system: ventilated front brakes, sheet-steel

deflectors forcing the air towards the braking system on the pivot, air

guides fixed on the under-part of the front of the body.

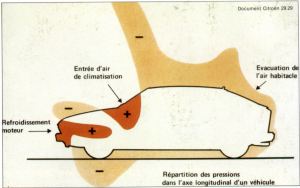

3 Pressure measurements

These measurements help to provide a partial solution to

the problems of engine cooling and passenger cabin air-conditioning.

Pressures are expressed as a non-dimensional coefficient

independent of speed:

Cp = P-Po

1/2 V2

Bernouilli's

equation : 1/2 pV2 + P = Constant along an air fillet is valid as a

first approximation for the front of the vehicle. It proves that

high-pressure areas have low air speed. Conversely, where the air

fillets cling to the body, there is a depression. (The drawing will

help you to understand this relation between air speeds and pressures

at any point).

Pressure

measurements make it possible to trace isobars (lines perpendicular to

the air fillets visualising the lines along which pressure remains

equal at a given value) on the vehicle's form.

The

choice of the position of the air inlet for passenger-cabin

air-conditioning will lie in the pressure zone at the foot of the

windscreen.

4 An air of economy

The

power that the engine must develop in order to overcome different forms

of resistance (apart from accelerations and gravity) is represented by

the formula:

W wheels = N. Wm = 1/2QCxSV3 +f. M.V.

where:

-

W wheels = power on driving wheels

-

N = transmission efficiency

-

Wm = power on engine output shaft

-

Q = air density

-

S = frontal area of car

-

Cx = coefficient of drag

-

f = frictional coefficient

-

M = vehicle mass

-

V = vehicle speed

-

1/2 CxSV3 = aerodynamic resistance

-

f.M.V. = running resistance

The

two following graphs represent respectively the formulae above, applied

to a current standard production car, and the car's consumption in

litres per 100 km according to speed. We can note the importance of

streamlining for speeds approaching and over 90 km/h /56 mph), and the

similarity between resistance and consumption curves, demonstrating the

important role played by aerodynamics in fuel saving.

|