|

||||||||||||||||||||||

|

|

|

| Hydractive 3 | |

|

At the Geneva Motor Show in March 2000, CitroŽn announced details of the new Hydractive 3 suspension system which has subsequently been fitted to the Mk 1 C5, the top of the range C6 and the current C5. |

|

|

|

|

|

|

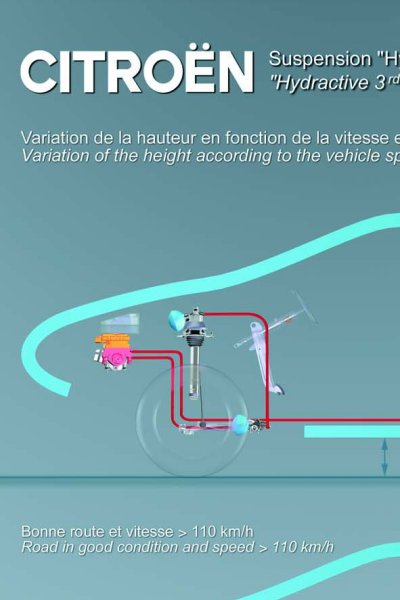

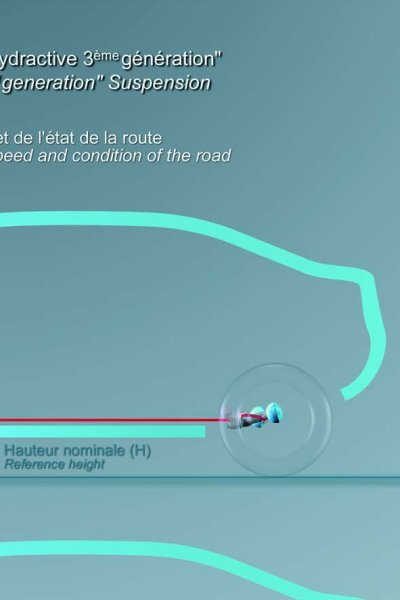

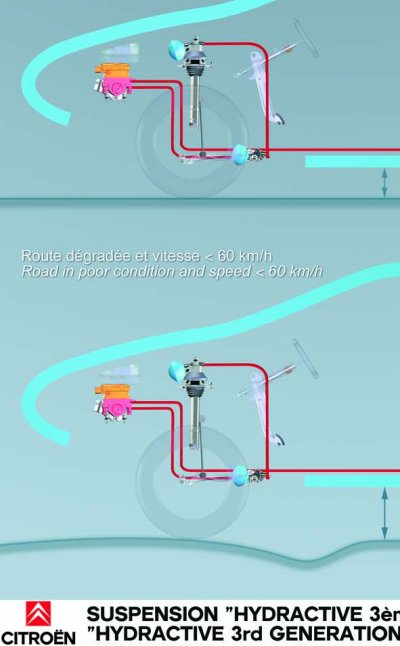

Characteristics of the suspension system The built-in hydroelectronic unit combines hydraulics with advanced electronics. This highly compact unit comprises three parts: An electronic

unit with a host of control laws stored in its memory, controlling the

electric motor and the stand-alone pressure generator in accordance

with the information delivered by:

An electric motor driving the pump in the stand-alone pressure generator. It comes into service solely when required, at rotation speeds of 2,300 rpm. A

stand-alone pressure generator designed to group flow, safety and

anti-dive/anti-squat functions, and equipped with a pump and four

electrovalves. The spheres are fitted with new multi-layer diaphragms that are not nitrogen-permeable. The pressure of the nitrogen (calibration) in the spheres therefore remains constant over time, ensuring that the suspension maintains all its properties.. The new exterior shape of the spheres (modified diameter/height ratio) has been optimised by computer calculations for a longer service life. The new hydraulic fluid is 100% synthetic. This composition gives it long-term stability while maintaining a high level of viscosity (low friction). Third-Generation Hydractive uses high-quality parts that require no maintenance for the first five years or 200,000 km. |

|

| © 2000 Julian Marsh | |